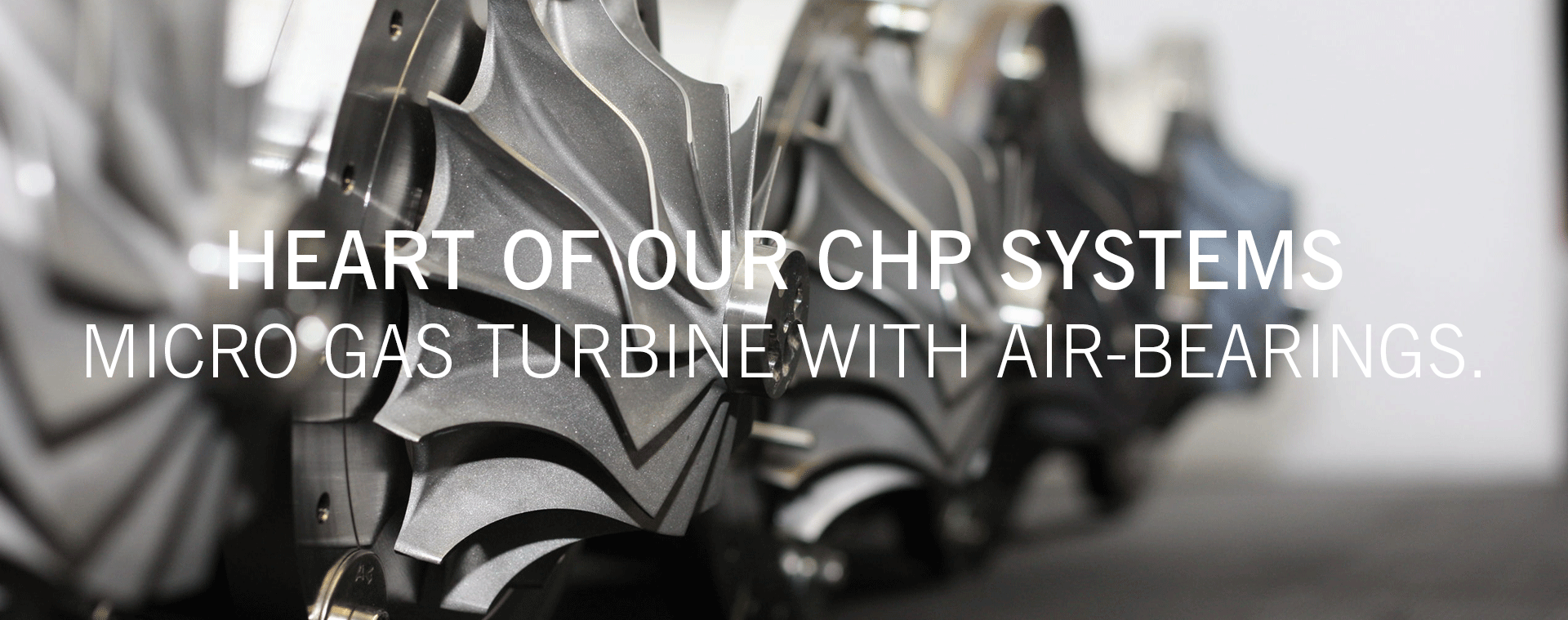

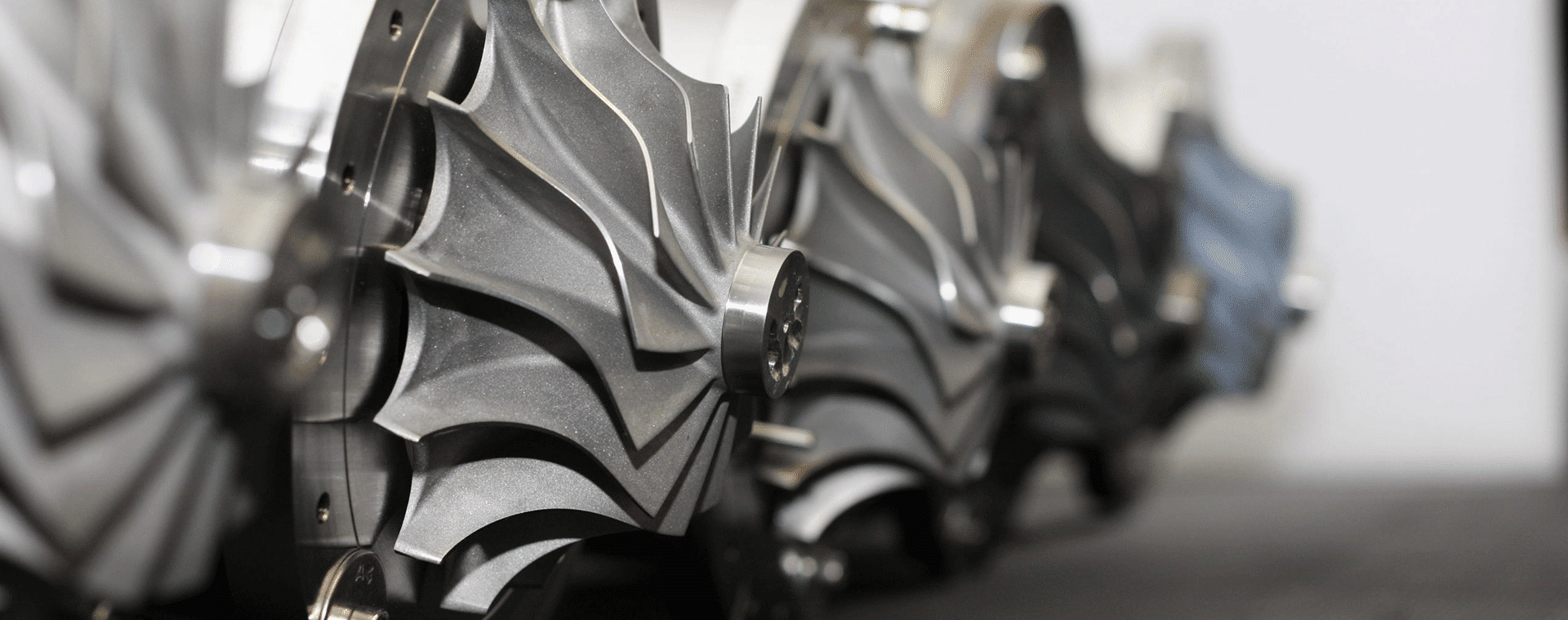

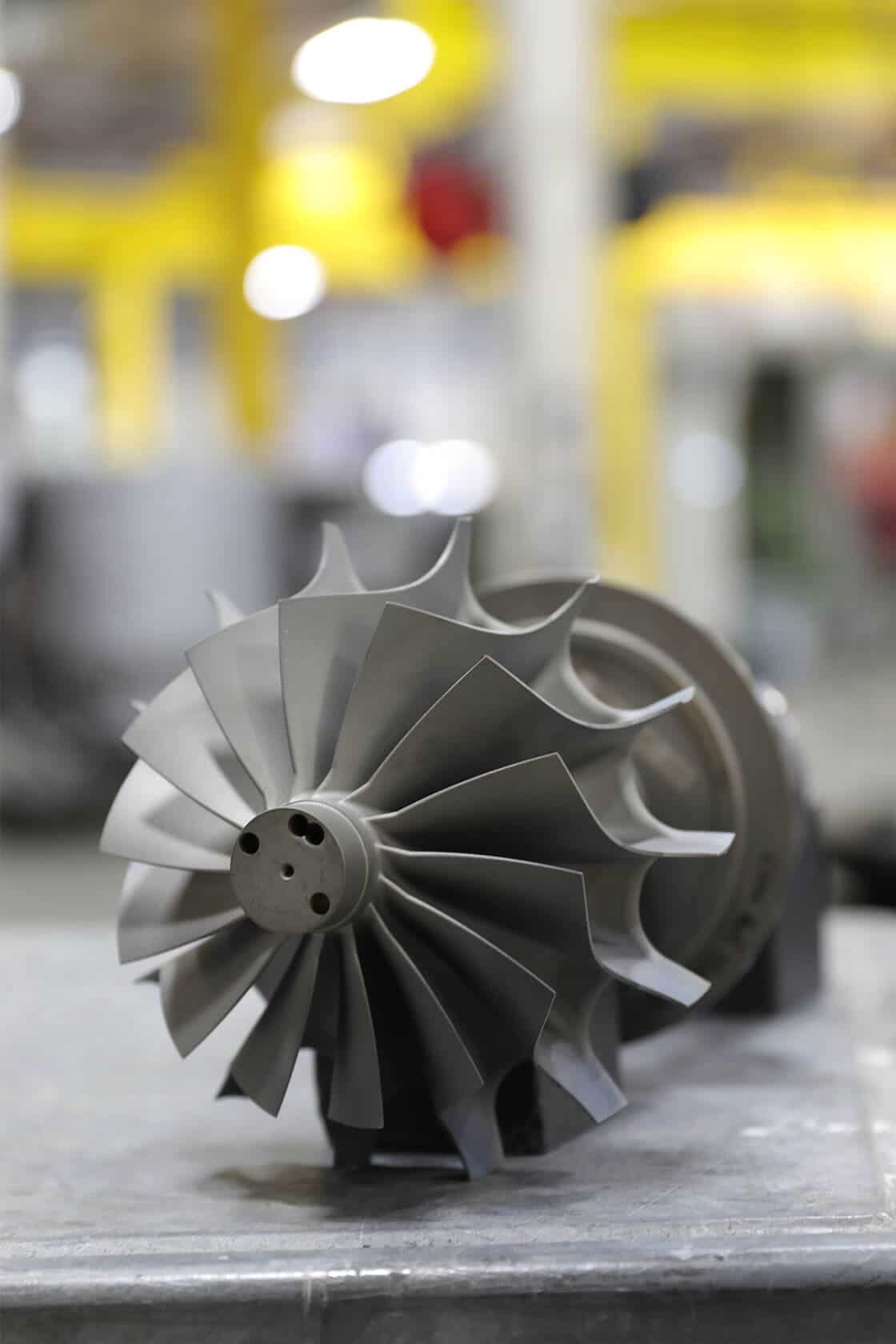

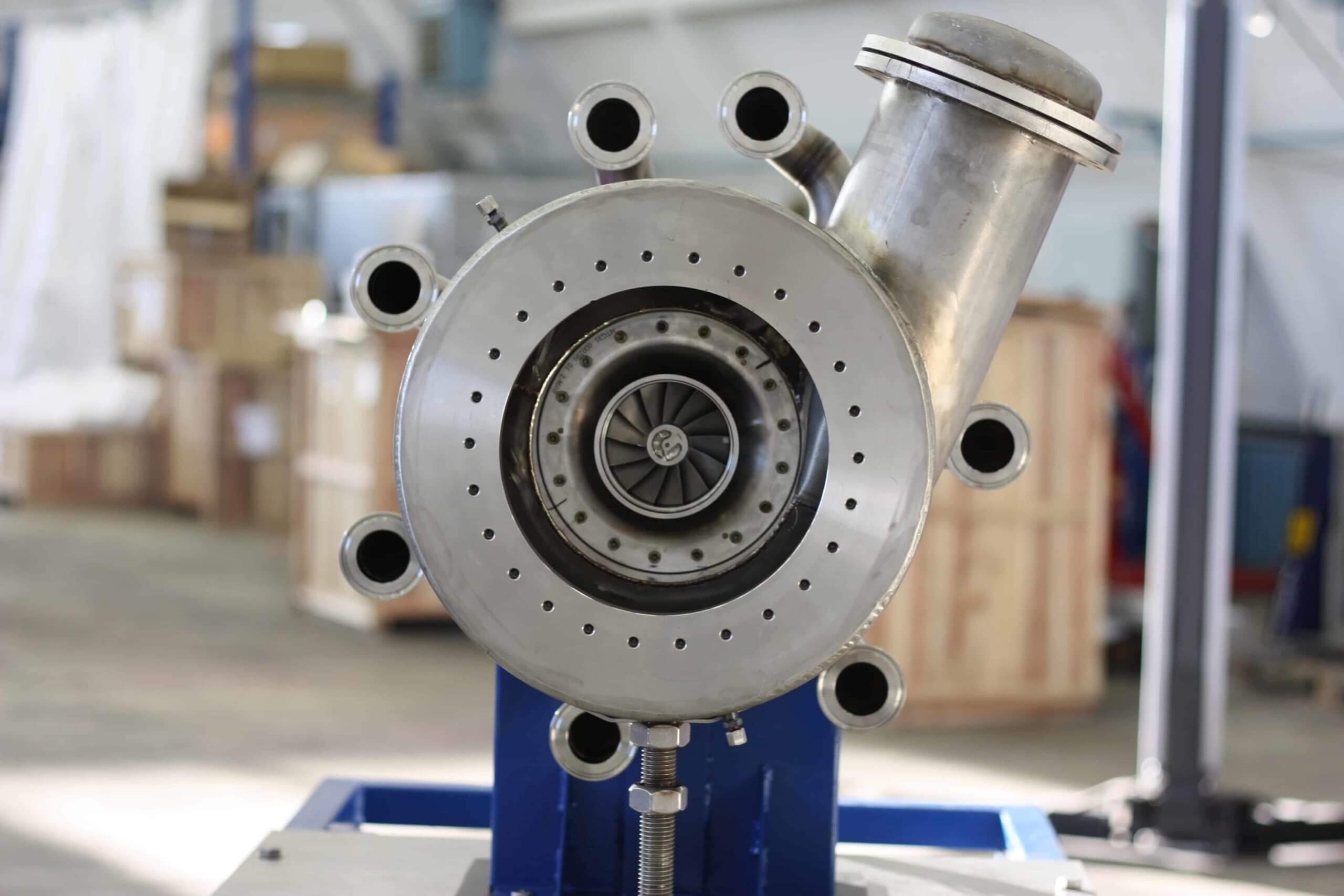

The core part of our Combined Heat-Power (CHP) system is the external combusted micro gas turbine. It converts thermal energy into green electricity. The compact turbo units with innovative air bearings have the advantage that, in contrast to conventional systems, no lubricants or coolants are required. This results in particularly low maintenance requirements and a long service life. In the very center lies the turbo group, which consists of the compressor wheel, turbine wheel and connecting shaft. The turbo group is the only moving assembly of the micro turbine. In addition to the turbo group, the generator, power electronics and control system also belongs to the micro gas turbine. For constant electrical energy conversion, a high-performance generator is directly coupled to the connecting shaft. It converts the mechanical energy generated by the external combusted micro turbine into electrical energy.

OUR EXTERNAL COMBUSTED MICRO GAS TURBINE

B+K has mastered micro gas turbine technology. Several systems in the 35-300 kW electrical power range have already been developed. This makes us one of the world’s leading players in micro turbine technology.

Our CHP ClinX also works closely with the absolute cutting-edge technology of selected cooperation partners. For example, with micro gas turbines from the American world market leader Capstone. The Capstone systems are compact, recuperated single-stage micro gas turbines.

RECUPERATED SYSTEM

The system is characterized by a high degree of burnout with low exhaust emissions (this allows you to reduce CO2 emissions to a required level) and is ideal to integrate into your existing process applications.

INNOVATIVE AIR BEARINGS

Air-born micro gas turbines from Berg & Kießling GmbH are characterized by passive foil sliding bearings that enable operation without lubricants and coolants. That makes the system extremely sustainable.

LOW MAINTENANCE

Future Energy generation. Thanks to the sustainable and environment friendly operation without lubricants and coolants, particularly low maintenance costs and a long service life are accomplished.

TECHNOLOGY LEADERSHIP

B + K is a one of the world’s technology leading teams in the field of micro gas turbine development. The company’s core objective is the sustainable generation of green electricity using renewable energies (e.g. wood chips or wood waste).

ENGINEERING "MADE IN GERMANY"

INTERIM & DESIGN

- Performance calculation for turbo machines (including circulation process calculation)

- Computer-aided design / construction (CAD)

- Flow design

- Analytical calculations

- Numerical calculations (FEM, CFD)

- AM-compliant component design (additive manufacturing)

- Efficiency optimization

PROCESS ENGINEERING & MATERIALS

- Integration in system concepts

- Fuel analysis

- Alloys for high temperature applications

- Ceramic materials for turbo machinery

- Coating technology

HOLISTICITY

- Component production (rotating parts, sheet metal processing, welding constructions, rapid prototyping)

- Thermal joint and heat treatments

- Component measurement

- Test bench development in the field of combustion technology, turbo machines and special machine construction

- Testing with multi-channel transducers and real-time evaluation options