ENERGY FROM WASTE HEAT

With the certified ClinX Heat technology, we combine waste heat with an externally fired micro gas turbine and thus convert green energy, such as electricity, heating or cooling. In this way, we guarantee energy generation without fossil fuels such as gas or coal, decentralized energy supply security, and a sustainable contribution to the fight against climate change.

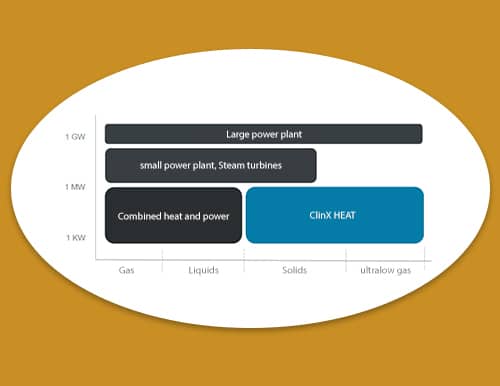

In the future, you and your company can rely on sustainable and green energy from waste heat! According to the Federal Environment Agency, final energy consumption (EEV) for heating and cooling accounts for a good half of total final energy consumption in Germany. Process heat alone accounts for a good 20% of the EEV. The term process heat refers to heat that is used in commercial and industrial processes to modify raw materials or workpieces, for example for production or central production processes such as casting, hardening, firing or drying processes. From a part of the process heat that is not used for manufacturing, production or processing, the waste heat, we convert energy in the form of electricity. At 66% of total industrial energy consumption, process heat is the most important commercial energy input, with heating and cooling required for different applications.

Percentage of process heat from total industrial energy consumption

BENEFITS OF ENERGY FROM WASTE HEAT

SAVE COSTS

Our energy is becoming more and more valuable as the resources are becoming scarcer every day. In the future, by using unused energy from production, manufacture or other processes and converting it into electricity, you will significantly reduce the energy costs on your side and boost the environment protection at the same time.

SAVE CO2

Use the waste heat from your production to generate clean electricity. You will then need less gas or oil and thus consume fewer resources and reduce CO2 emissions of your company.

NO INVESTMENT

Thanks to the efficient usage of waste heat, there is no need to install an additional plant for heat generation. Together, we make better use of what is already there – your waste heat.

INEFFICIENTLY USED RESOURCES

Electricity generation from waste heat of metal production and processing industry.

Electricity generation from waste heat of chemical industry or mechanical engineering.

Energy recovery from unused gaseous waste.

Electricity generation from waste heat of pyrolysis processes

ELECTRICITY FROM PROCESS HEAT

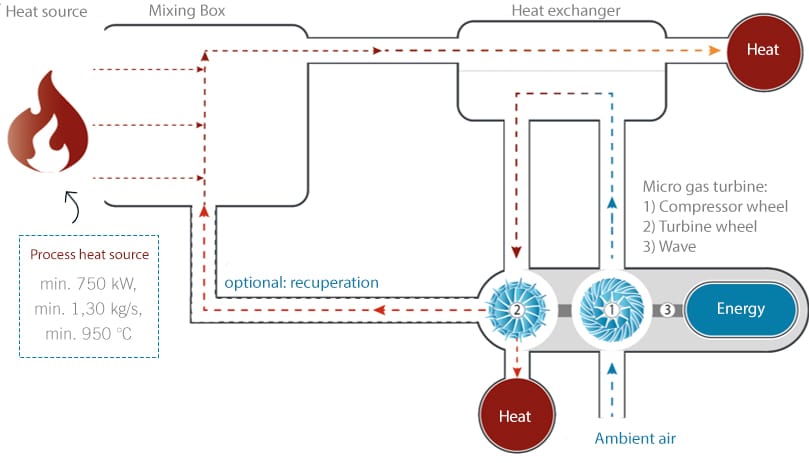

Due to the composition of the process gas and the process temperature, we use an external combusted micro gas turbine process (EFGT) as a basis. The process of the external combusted gas turbine in this case is other than that of a conventional gas turbine.

All detailed technical information can be found in the data sheets.

➀ The clean ambient air compressed in the compressor flows through the heat exchanger, to be guided and heated to the required turbine inlet temperature.

➁ After the hot air being expanded in the turbine, it will be used as process heat in the customer application. Whether the optional electrostatic precipitator is required depends on the exhaust gas composition of the heat source.

➂ After a heat sink, the EFGT can be further connected and generate electricity from the waste heat.

Excursus on the subject of heat exchangers

The heat exchanger is not only characterized by its high temperature resistance, but also by its resistance to the chemical effects of the combustion gas. The flow-optimized design can be scaled to different power classes.

Excursus on the topic of micro gas turbines

The micro gas turbine is the heart of the CHP system. The driving unit of the micro gas turbine is called a powerhead. The powerhead consists of the turbo group, which consists of the compressor wheel, turbine wheel and connecting shaft. The turbo group is air-born so that no lubricants or coolants are required. The powerhead including the turbo group is the central element of the micro gas turbine. Other components of the micro gas turbine are the generator, power electronics and control units.

What is the unique selling proposition of an EFGT?

The unique selling proposition of EFGT: Your fuel flexibility and decentralization. With a power range between 60 – 200 kW electrical, the EFGT identifies its unique.